Thermal Imaging for Manufacturing Industries.

Predictive maintenance and RCM programs at manufacturing facilities regularly use thermal imaging for inspecting a number of mechanical and electrical components.

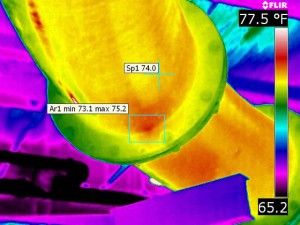

An overheating roller bearing is clearly visible during this infrared inspection of the production line.

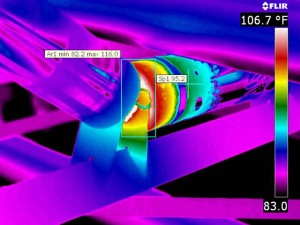

An infrared image that integrates accurate temperature data provides your maintenance crew with crucial information about the condition of all kinds of equipment. As a non-contact measurement tool that also makes invisible heat issues visible, thermal analysis let technicians inspect production equipment more safely even at peak operation. Along with troubleshooting, thermal imagers can also help optimize the production process itself as well as monitor quality control.

Mechanical Equipment

Some examples of mechanical equipment where thermography is used:

- Pumps: Overheated connections, fuse problems, overloaded electrical cables, etc.

- Process valves: Open, closed, leakage

- Storage tanks: Sludge levels

- Pipelines: Check if and where there are anomalies, for example locate build-up of scale, etc.

- Motors: Overheating bearings, misalignment, overheated windings

- Conveyor belts: Overheated bearings

- Furnace inspections: With a special camera designed to “see through flames” for high temperature industrial furnace applications, ideal for monitoring all types of furnaces, heaters and boilers

Tank levels can be quickly determined without manual measurements and the associated time required to use the appropriate PPE.