Thermal Imaging Helps You Detect, Troubleshoot and Fix Problems to Prevent Costly Shutdowns and Outages.

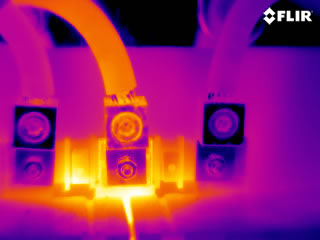

Electrical equipment tends to heat up before it fails. Often times the problem is undetectable until equipment or connections fail. Fortunately, thermal imaging can make those hot spots clearly visible so they can be caught in time to investigate further, plan repairs, and get the equipment fixed before it turns critical. Thermal image inspections of electrical cabinets, breaker panels, fuses, bolted connections, and switchgear can give an indication of impending trouble that otherwise would likely be missed during routine preventative maintenance inspections.

Infrared Thermography can quickly identify electrical connection issues while the equipment continues to operate under load.

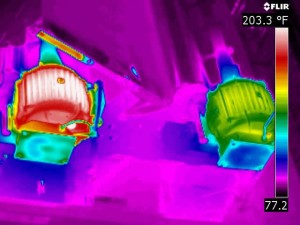

A non-infrared inspection would most likely miss a situation like this where one of the motors is seriously overheating but looks normal to the naked eye.

A skilled infrared technician can provide high quality thermal images that relay clear concise information on equipment condition without having to shutdown critical pieces of equipment or processes.